To ensure that we keep our customers on the cutting edge of metal additive manufacturing, we work with a network of innovative partners in advanced materials, software technologies, and more.

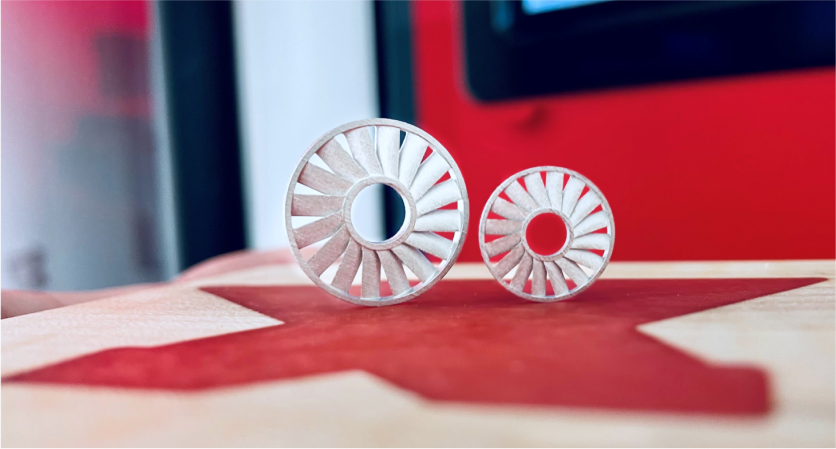

The European REProMag project (2015-2017) focused on research regarding the additive manufacturing of complex geometries with the same performance profile as metal injection molded (MIM) parts. The project helped to lay the foundation for the Incus lithographic printing process for manufacturing highly precise metal parts. The project received funding from the European Union’s Horizon 2020 Research and Innovation Program (grant agreement 636881).

The Vienna Business Agency Innovation Funding Program was started in 2019 to support the development of innovative technological solutions within the city of Vienna. Incus was a part of the PRIMUS project and developed a new 3D-printing concept with a high-performance exposure system, allowing a new class of feedstock with finer metal powders. The use of finer powders is relevant for special performance materials, including refractory applications (Tungsten) or Cutting Tools (Tungsten carbide-cobalt (WC-Co).)

This 18-month project tested 3D printing Lithography-based Metal Manufacturing (LMM) process in a micro-gravity environment whether it is possible to print materials in a lunar base using scrap metal or existing surface materials. Ultimately, this research could help to pave the way for future lunar settlements as it could address issues related to supply chains and acquiring supplies from Earth.

Head of Sales