Incus was founded at the end of 2019 around a unique metal additive manufacturing technology, Lithography-based Metal Manufacturing (LMM), that reduces production costs and time for small and mid-scale additive manufacturing of metals.

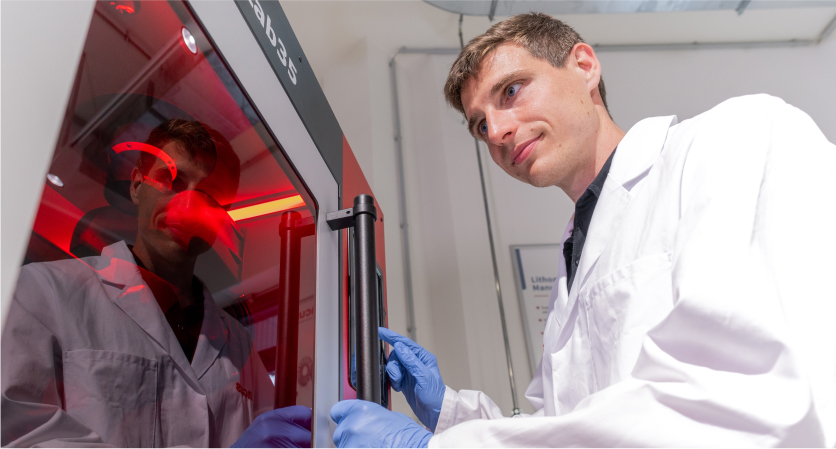

The first flagship 3D printing solution, the Hammer Lab35, was shipped in March 2020 followed by serial machine production in 2021. Within the last two years, the Incus team grew from 6 to more than 25 experts from all over the world. The production facilities in the newest innovation hub in Vienna, Austria, have recently doubled in capacity. With these expansions of capacity and expertise, Incus is working towards scaling up to mass-production.

In 2006, a new lithography-based additive manufacturing technology for ceramic materials was invented at the Vienna Technical University. Five years later, Lithoz GmbH was founded to commercialize the technology for ceramic materials. In 2015, during the European research project ReProMag, a new 3D printing approach for metals was successfully developed within Lithoz by the founder of Incus, Dr. Gerald Mitteramskogler.

This approach was dedicated to transferring the great results from ceramics to the printing of metal powders. After four years of further research, the results convinced Lithoz and investor AM Ventures Holding GmbH to intensify the development and create a separate company in 2019: Incus, focused solely on 3D printing of metals.

Gerald put his extensive technical knowledge of additive manufacturing of high-performance ceramics and metals into creating faster and easier way of producing high-precision parts. That’s how name “Incus” came about: Incus means ‘anvil’ in Latin, referencing our new approach on the centuries-old, traditional process for shaping metals.

The Incus team is made up of creative experts with the knowledge, expertise and drive to apply their technologies and solutions to your metal additive manufacturing needs. Our goal is to meet the challenges of our customers and their specific applications with a tailor-made, solution-oriented approach.

Gerald is a mechanical engineering professional with 11+ years of experience in additive manufacturing. He received his M.S. and Ph.D. in Mechanical Engineering from TU Vienna. Understanding the challenges of metal manufacturing, he founded Incus to introduce innovative 3D printing technology for producing complex metal parts.