Incus has recently partnered with the European Space Agency (ESA), OHB System AG and Lithoz GmbH in a joint project to develop and test 3D printing in a micro-gravity environment. On Earth, the Incus Lithography-based Metal Manufacturing (LMM) process produces parts with excellent surface aesthetics and similar material properties compared to Metal Injection Molding (MIM).

One of the major challenges in maintaining a lunar station is ensuring a constant supply of goods. In addition to supplies, research materials and equipment, spare parts are also needed in case of any failure of individual components. Since long-term missions have to be self-sufficient, the space experts from the ESA have shown great interest in the use and reuse of both existing lunar surface materials and recycling of lunar base materials, derived from production waste and end-of-life items. The ability to manufacture necessary items and spare parts, on board and on demand, will help reduce the cost and volume of cargo missions from Earth, as well as minimize production waste.

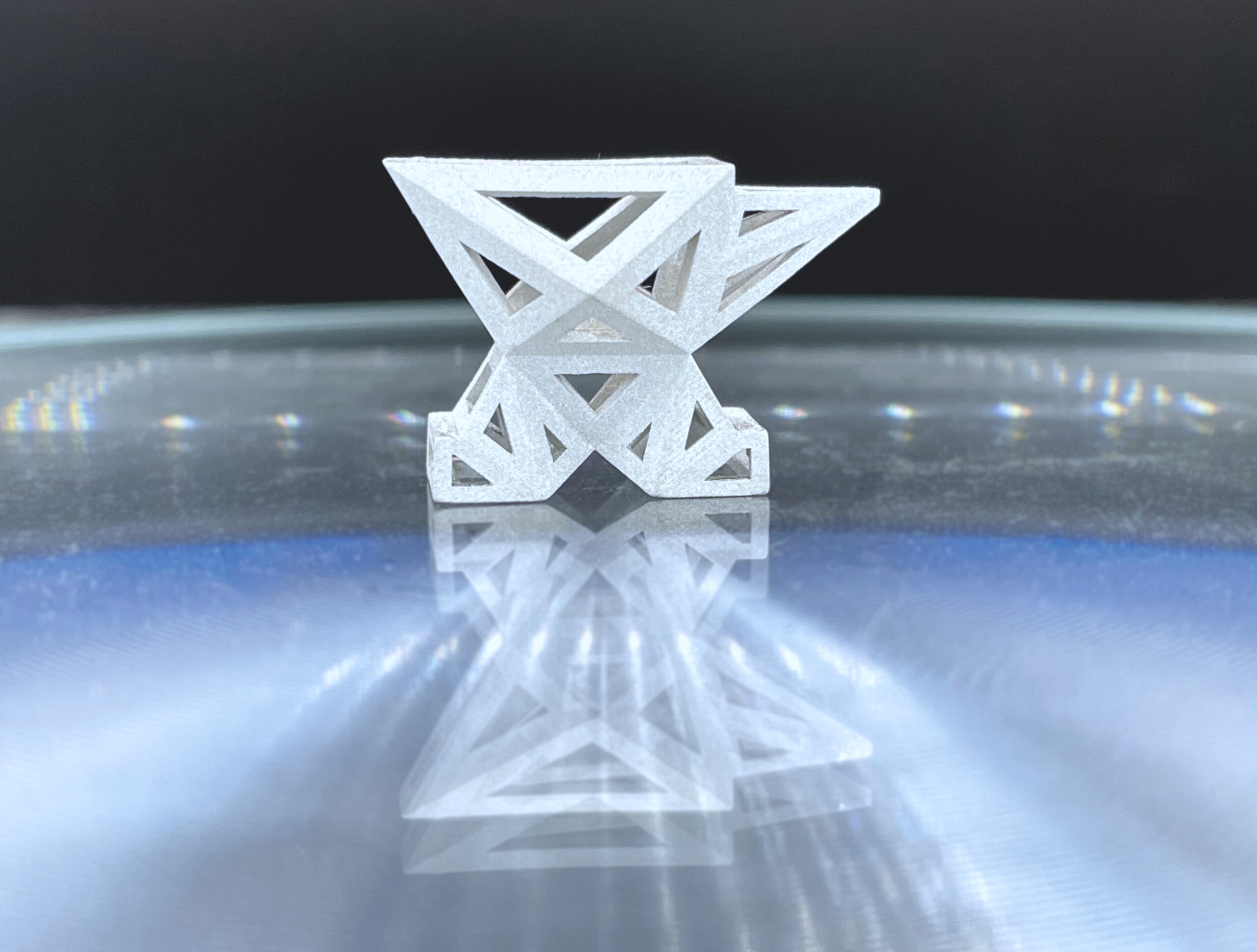

This LMM technology offers a potential solution as it can produce spare parts from recycled metal waste, which could enable the utilization of recycled powders from scrap metals that are available on the Moon. In contrast to the currently predominantly used direct metal laser melting techniques, the LMM process uses a paste or suspension as feedstock and does not rely on the use of highly spherical gas-atomized powders or support structures. The production of dimensionally accurate components separated by the thermal demolding process does not require any time-consuming, mostly manual reworking and is completely safe for the operator.

The goal of the 18-month project is to assess the feasibility of processing scrap metals available on the Moon’s surface to produce a high-quality final product via a zero-waste process. The assessment will take into account the constraints of a space environment – for example, considering the potential contamination of the metal powder with lunar dust. Further evaluation of the influence of impurities on the sintering and result of the final microstructure will lead to optimization of the binder quantity and type, as well as the development of a sustainable manufacturing chain in space.

“We at Incus are excited to be a part of a project that will test the capabilities of our LMM technology for use in space,” comments Incus CEO Dr. Gerald Mitteramskogler. “Our solution could be a great fit to meet the challenging requirements of producing parts in such an environment.”

Antonella Sgambati, Human Spaceflight System Engineer at OHB System AG, states: “The possibility of reducing our dependency on Earth by utilizing existing lunar surface materials and recycling lunar base scrap metal represents the only solution to guarantee a sustainable settlement. This project and this novel LMM process will be important steps in making such a settlement a reality due to the fact that this technology could have a chance to operate successfully in space."

“Lithographic techniques such as the ones developed by Incus and Lithoz allow the combination of high precision 3D printing with high-performance metals and ceramics, while still remaining extremely resource-efficient. While these concepts have been successfully demonstrated on Earth, the activities of such projects are crucial for filling technological gaps and enabling the implementation of additive manufacturing in a space environment.” describes Dr. Martin Schwentenwein, Head of Material Development at Lithoz.

Dr. Martina Meisnar, Materials and Processes Engineer at ESA, remarks: “Out-of-Earth manufacturing is a very interesting topic that is being investigated by the European Space Agency with great effort. The goal is to refine these manufacturing concepts towards demonstration on Earth and ultimately for implementation in space”.