The LMM technology has been chosen by Upnano GmbH to accelerate the research & development of new materials for innovative Micro & Nano 3D printing.

Comprehensive testing is essential in the design and the development of new materials to make the translation from research to customer applications. In materials science, the physical testing methods are well established and standardized. However, to fit the needs for novel manufacturing processes, such as Micro- and MesoPrinting by UpNano, the testing methods need to be adapted. As printed parts are scaled down in size, the dimensions of testing specimens need to be adapted accordingly. With the aim to bridge the gap between microprinting, mesoprinting and nanoprinting, UpNano expands the size scale of accessible printed parts. In scaling down test specimens accordingly, well defined material performance at low dimensions can be guaranteed.

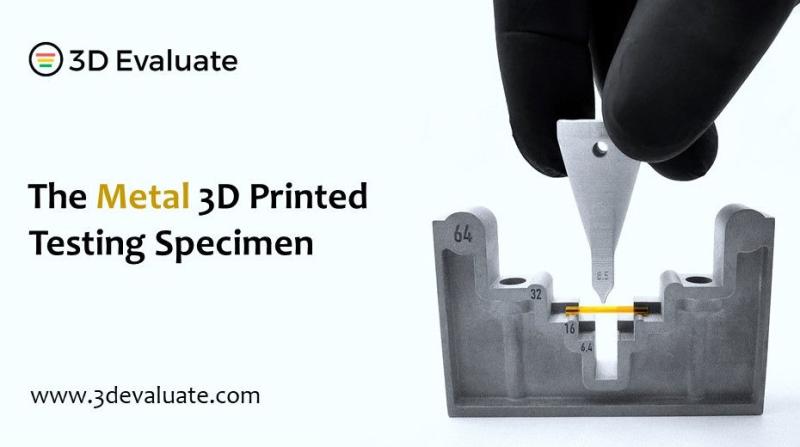

The stamp and the die used in the UpNano test method are designed to be multi-functional and integrate four three-point-bending test arrangements into one setup, making this method the “Swiss army knife of 3-point bending”. The Incus metal 3D-printing approach was the ideal production technology for UpNano, as it enables the quick redesign and production of the parts needed for the test setup.

You can read the whole story here.