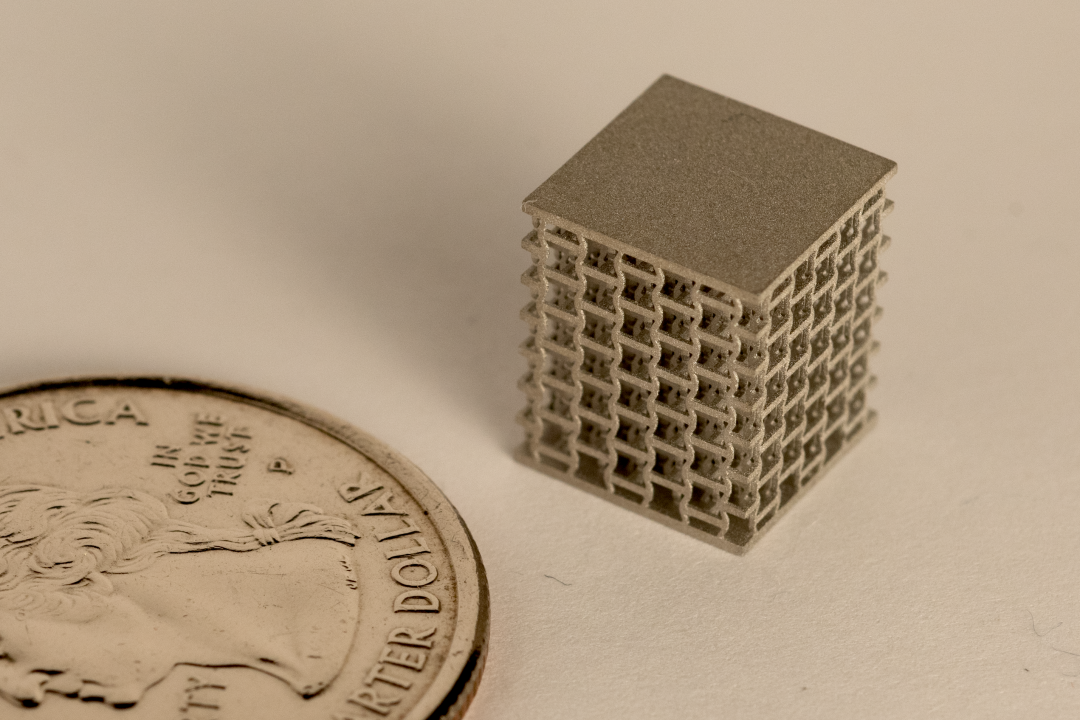

We are happy to announce a collaborative research initiative between Incus GmbH and the NanoProbe Group at Yale University, focusing on the fascinating realm of auxetic structures. Spearheaded by Yale’s talented Undergraduate Research Assistant, Jacob Eldred, and the NanoProbe Group, renowned for their work in materials characterization and discovery, this collaboration delves into the innovative design and production of unique lattice structures.

The lattice structures designed by Jacob Eldred aim to exhibit a negative Poisson’s ratio, causing the sample to become thinner when compressed or vice versa. This intriguing behavior is attributed to the special design of the geometrical features, presenting challenges for conventional manufacturing processes.

The Hammer Lab35, Incus’ cutting-edge 3D printer, played a key role in bringing these intricate structures to life and assess the performance of both the structure and the material.

The sample’s exterior dimensions measure 9.3 x 9.3 x 10.20 mm, with a minimum lattice thickness of 150μm and a volume fill level of only 9%. The samples were printed without any support structures and no post-processing was applied, such as machining, sand blasting, or chemical surface treatment.

The first measurements revealed a negative Poisson’s Ratio: ν = -0.59, @ ε = 6.1%, approximately 2 times the yield strain. More detailed data and publications will follow.

These auxetic structures open doors for applications in stress absorption and the biomedical field. When printed in 3-dimensional forms, as opposed to extruded in 2D, they can also function essentially as multi-axial springs.

This collaboration exemplifies the power of merging cutting-edge technology with innovative research, and we look forward to exploring further possibilities in the realm of advanced materials and structures. Stay tuned for more updates on this exciting venture!