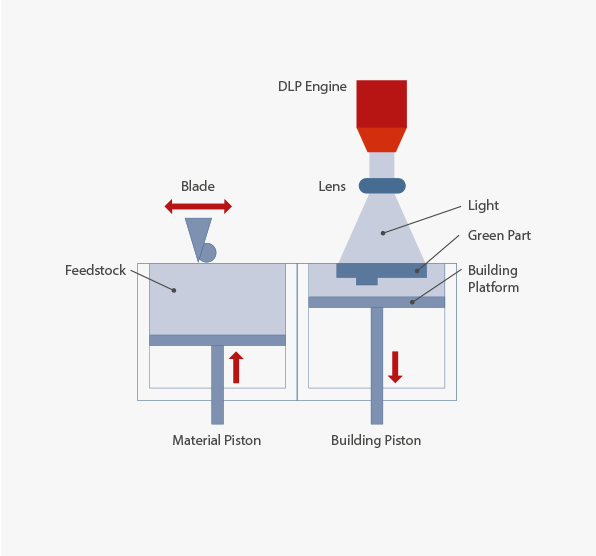

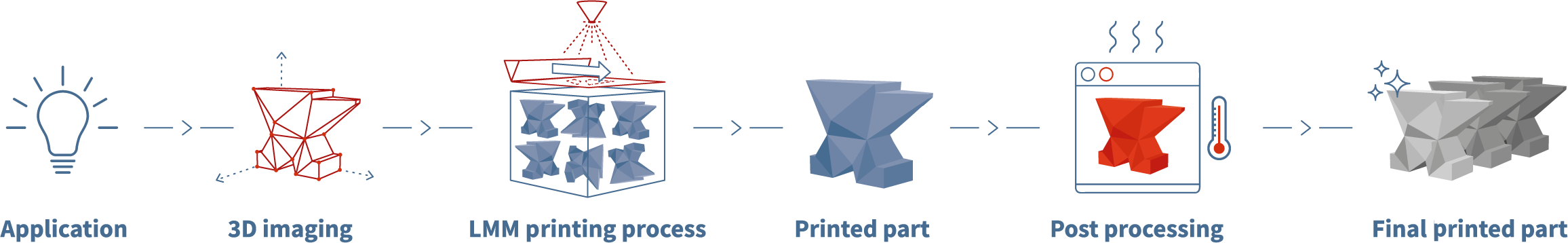

Incus 3D printers are based on the Lithography‐based Metal Manufacturing (LMM) technique. This manufacturing method is centered on the principle of stereolithography and uses photopolymerization to build parts in a layerwise process via exposure with light. In comparison to conventional stereolithography processes, the raw material (feedstock) consists of metal particles which are dispersed in an organic binder phase. Incus feedstocks exhibit unique properties instrumental for the LMM process.

At room temperature, the feedstock remains as a solid block, but can be easily liquefied through application of heat. This is done by a heated blade which coats thin layers of feedstock onto the building platform. Each material layer is exposed individually, thereby selectively triggering photopolymerization. This process is repeated until the entire part geometry is manufactured layer by layer. Because of the active cooling in the printer, the surrounding non-cured feedstock solidfies as well, thereby re-creating the original feedstock block in which the printed parts (“green parts”) are incorporated. Hence, the green parts are supported by the unused printing material and no additional support structures are required.

After the printing, the green parts can easily be released by liquefying the feedstock block (“de-caking”). The uncured material is collected and can immediately be used again for printing. The green parts then undergo a debinding and sintering step in which the organic binder is removed and a dense final metallic part is produced.

The special properties of Incus feedstocks allow printing of arbitrary geometries without using any support structures, because the feedstock block supports itself. Consequently, no material is wasted on support and all unpolymerized material can be recycled, making LMM a particularly sustainable 3D printing method. Also, a wide range of metals from stainless steel to titanium, copper, tungsten, precious metals, carbides and many more are processible.