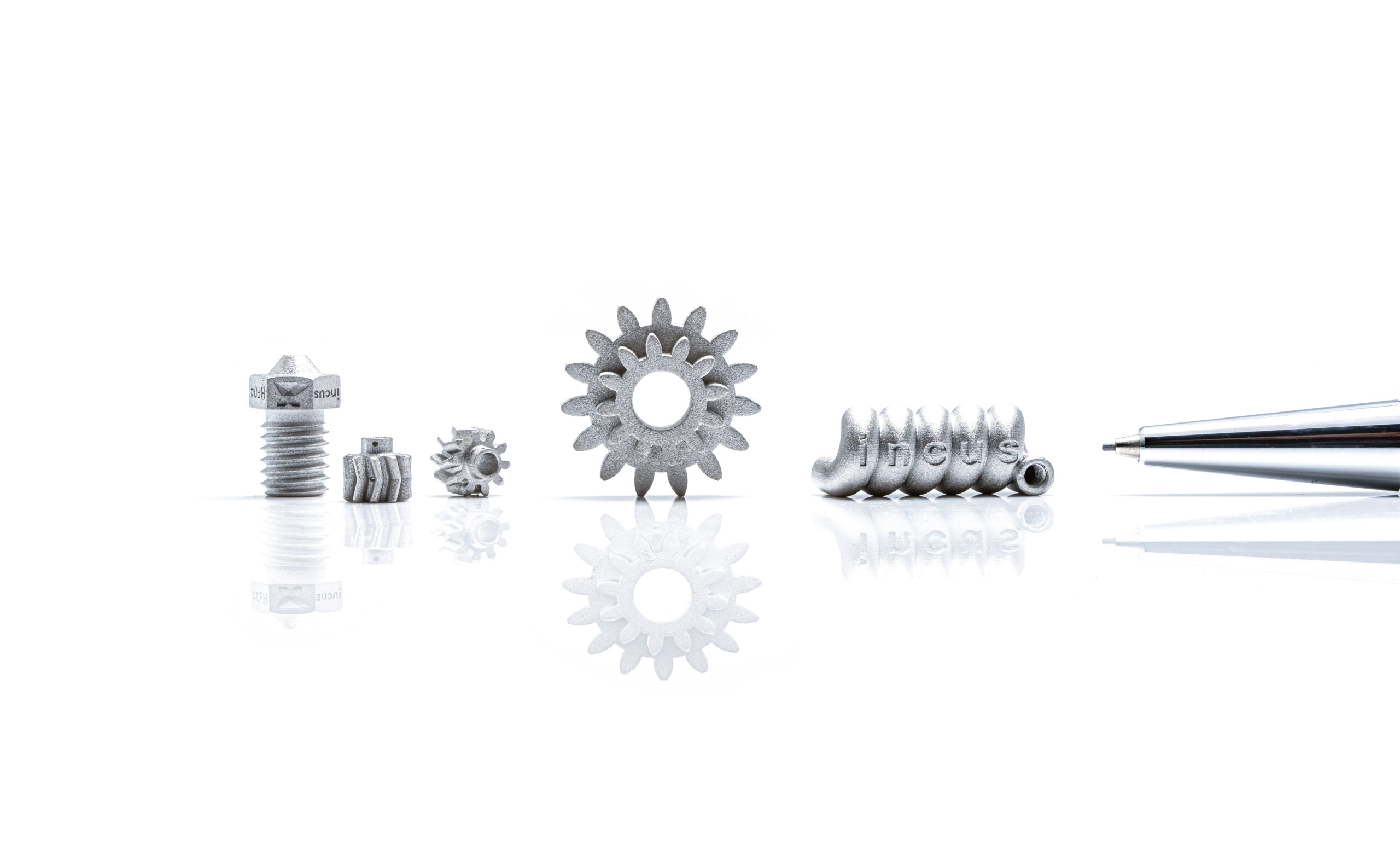

Incus technology allows the manufacturing of fine channels, undercuts, and inner structures in highest quality. The combination of exceptional surface quality after printing, industrial mechanical properties, and the ability to print maximum part complexity offer excellent options for the tooling sector.

Typcial applications include nozzles, drill heads, turbine wheels, customized screws and bits, and many more.

The high resolution of Incus technique and the capabilities to process various metals, in consistent quality and precision enables LMM to thrive in the electornics industry. Potential materials for the electronics field are electric and thermal conductive metals as well as high surface hardness components.

Typical applications include mobile phone cases, SIM-card holders, heat exchangers, and cooling devices.

Many applications in the medical sector such as devices for surgeries and laboratory equipment are often niche products with complex geometries and fine features produced in smaller series. Incus ability to process biocompatible and safe for medical use materials with highest accuracy establishes LMM as an ideal process for medical applications.

Typical applications include dental brackets, crowns, bridges, implants and surgical grippers.

With LMM 3D printing, designers can produce sophisticated patterns and geometries that would be otherwise incredibly difficult to craft. Our technology enable processing of various precious metals and unites the optics of traditional manufacturing with highest accuracy and freedom of design. Customized products and unique individual pieces exhibiting excellent surface aesthetics can easily be accomplished.

Typical applications include watch cases, necklaces, rings, and bracelets.

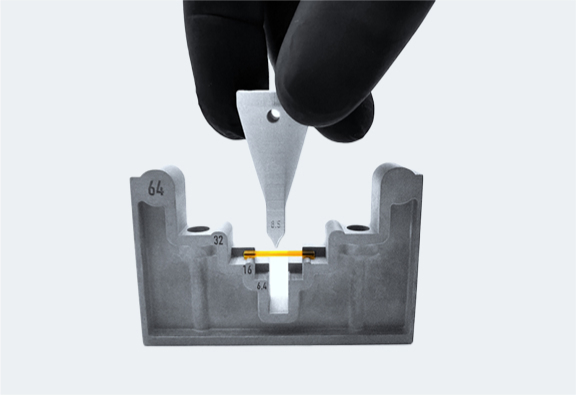

With LMM, the production of single parts and quick geometry adaptions can easily be achieved, while minimal material is consumed. This makes the technology the ideal solution for R&D purposes. Full control over material properties and machine parameters enable fast design iterations.

The picture shows a customized 3-point bending testing device specifically manufactured to measure the properties of small and flexible specimens.