Untreated parts that still need to be sintered are commonly referred to as green parts. After removing the binder, including partial removal, parts are called brown parts. This naming convention has its origin in ceramic production. Sometimes, the fully sintered parts are referred to as white parts, however this is uncommon in powder metallurgy.

The binder is a multicomponent polymeric mixture that holds the powder together to keep the shape. Usually, this is a polymer or mix of polymers.

In metal injection molding (MIM), the mixture of the binder and the powder is referred to as feedstock. Due to certain similarities between the materials used in MIM and LMM, Incus decided to adopt this same naming convention.

Solvent and catalytic debinding

For some materials, full thermal debinding is not possible or not economical, this could be due to oxygen sensitivity or high sintering activity at low temperatures of the metal, or high thermal stability of the binder. In those cases, other methods can be used. In solvent debinding, the parts are placed in an appropriate solvent that dissolves a fraction of the binder. In some cases the temperature also needs to be slightly elevated, sometimes room temperature can suffice.

In catalytic debinding, the parts are heated to relatively low temperatures in an atmosphere that catalyzes the decomposition of the binder. Usually, this atmosphere contains vapourized acid, e.g. nitric acid. The solvent and catalytic debinding of LMM parts is possible as an alternative to a single thermal debinding approach. This reduces the load of organics introduced into the debinding furnace without heat treating the metal and enables the use of shorter thermal debinding cycles.

Theoretical density

The theoretical density is the maximum achievable density of a material. In reality, imperfections affect the density. In powder metallurgy porosity has the biggest impact on density, and also affects most mechanical properties negatively. Above a certain threshold at around 96% of the theoretical density, the effect of porosity is mostly negligible. For ease of understanding, the percentage value of theoretical density is used instead of absolute density values, since even the density of a single alloy can vary heavily within the defined composition range.

Oxidative atmosphere

In an oxidative atmosphere, oxidation can take place. This chemical reaction commonly occurs in connection with oxygen. An oxidative atmosphere can be useful in debinding, since the burning of the binder reduces the necessary temperature and energy. However, the metal powder will also be oxidized, and this metal oxide will inhibit sintering. Therefore, the oxide must be reduced, which is usually done using a reductive atmosphere. The most commonly used oxidative atmosphere is air, due to its ease of use and abundance.

Reductive atmosphere

Reduction is the opposite reaction of oxidation, and always occurs simultaneously. Therefore, a reductive atmosphere is composed of a gas, that can easily be oxidized, thus acting as a reducing agent.

The most commonly used reductive atmosphere contains hydrogen gas. Due to it being considered explosive, pure hydrogen requires proper equipment. However, by diluting the hydrogen using inert gas, these safety regulations can be avoided, but the reductivity of the gas mixture, generally known as forming gas, is also lowered.

Inert atmosphere

Inert substances do not react. What is considered inert can vary by the given reference material. For example, nitrogen gas is mostly considered inert, but can form nitrides with certain alloys, e.g. titanium alloys or 316L stainless steel. Some generally considered inert atmospheres are noble gasses, like argon and helium.

Strength

Strength is the ability to withstand stresses without failing. For example, during tensile tests there a several commonly given values that characterize the material: Re, Rm and Rp0.2. Re is the yield strength or elastic limit. If this stress is exceeded, permanent plastic deformation takes place. Rm is the ultimate tensilte strength of the material before it breaks. Rp0.2 is the offset yield at 0.2% of plastic deformation. This is an arbitrarily chosen point of the stress/strain diagram that has proven useful for comparing metals.

Toughness

Toughness is the resistance of a material against fracture. It is closely related to strength, but also includes the ductility of a material. Related values to this are the critical stress intensity factor KIC, which measures the resistance against a single crack, and fracture toughness, which is the energy required by area to break a part.

Our user-friendly data preparation software is provided by Incus as part of the machine package. Additional software features can be added according to your need and could include in-line monitoring, creation of a print report, or access to all printer parameters. If more sophisticated data preparation is required, Incus is happy to recommend third party software solutions.

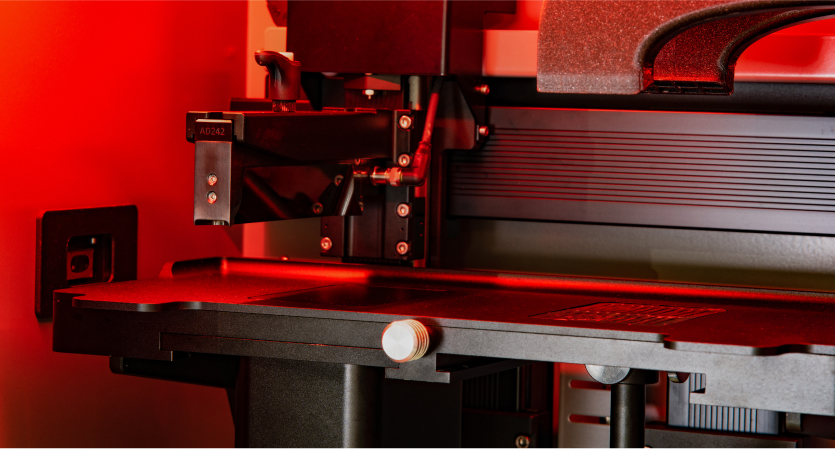

In the Hammer Lab35, parts can be placed inside the whole building volume of 89.6 x 56.0 x 120.0 mm (X/Y/Z) without supporting structures. Besides the physical space of the printing volume there are no other restrictions concerning the green part size. However, please consider design recommendations concerning the debinding and sintering of green parts, which are similar to those in Metal Injection Molding. We will post guidelines soon.

The Hammer Lab35 is an industrial 3D printing solution which can print 316L stainless steel, titanium 64, brass, tungsten, hard metals, diamond and many more. So far only one material can be printed at a time. Please contact us if you are interested in development projects concerning multi-material printing.

Yes, there are no technical restrictions for printing precious metals, such as silver, gold or platinum. Contact us if you are interested in a development project for precious materials.

The printing time is about 10 mm/h @ 25 µm layer thickness, so the whole volume is used in 12h. The speed doubles when using 50 µm as a layer thickness.

The minimum wall thickness always depends on the part geometry. Free standing ribs or fins could be printed down to 200µm wall thickness.

The achievable densities and mechanical properties are similar to material processed by MIM. LMM printed and sintered 316L stainless steel can reach a density of 98.2 – 99.0%, based on a theoretical density of 7.87 g/cm³.

The standard resolution of the printer is 35 µm in X/Y, which corresponds to 730 dpi. Depending on your application, the optics can be adapted if higher resolution is needed.

The possible level of detail for text or ornaments is down to 1-3 Pixel (35 µm – 105 µm) depending on the part.

For cubes of 10 mm we achieved an accuracy and repeatability of +-20 µm in the sintered state. Smaller parts yield an even higher accuracy.

The roughness of the sintered part largely depends on the used powder. Typically, we achieve Ra values of less than 5 µm in every direction without any surface treatment.

The shrinkage while sintering is approx. 16-20% in every direction. The shrinkage depends on the type of metal, the part geometry, the powder loading, and the sintering conditions. With LMM, iteration loops can be done quickly to get the right shrinkage coefficient. LMM follows the same design principles for sintering as Metal Injection Molding. To avoid deformation due to gravity, the design of the part could be adapted or sintering support could be used.

No, after the printing the mechanical strength of the green part is fully developed. They are not UV sensitive and no post-curing to enhance the strength is necessary.

Yes. The parts created with LMM technology show mechanical properties equivalent to a metal part made with Metal Injection Molding. Detailed information can be found on the Technology page.

Head of Sales & Marketing